Download our most up to date information right here...

Vista GeoScience Services Overview

Vista GeoScience Subsurface Imaging

Vista GeoScience Capability Statement

Improved Soil Gas Sampling with Sorbent Tubes

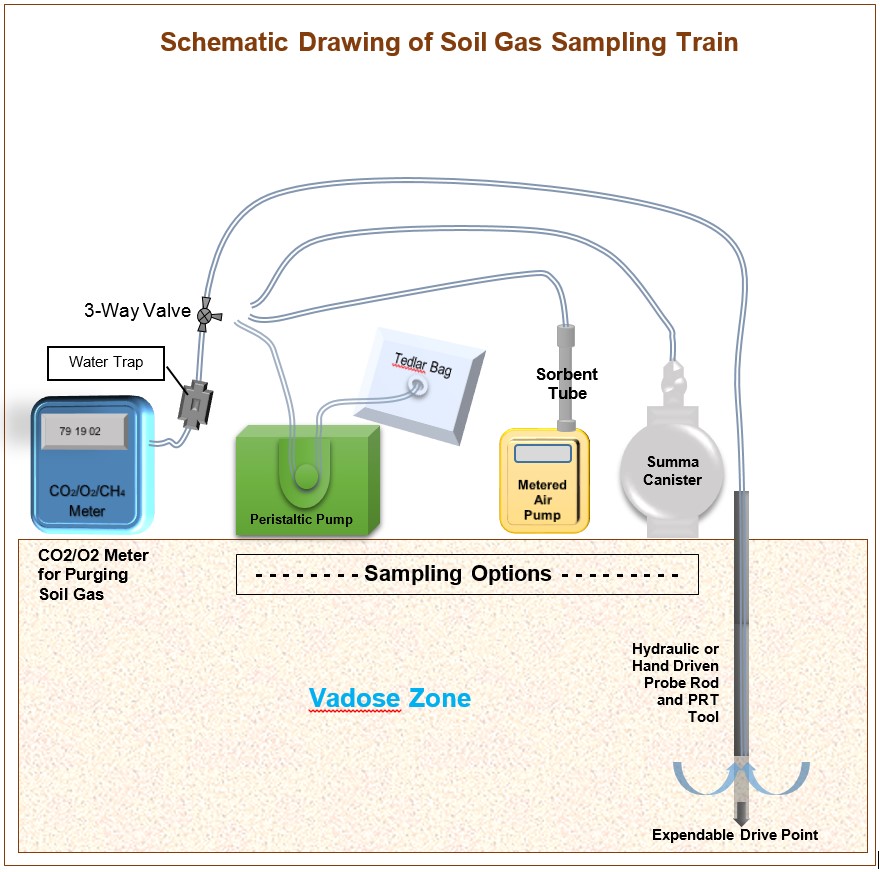

Traditional soil gas screening methods often rely on containers like Tedlar® bags or syringes and require direct injection into a GC or a standard purge-and-trap unit built for soil or water samples. These methods typically result in high reporting limits—well above indoor air screening or action levels. To overcome this, Vista GeoScience developed an advanced sampling technique based on EPA Methods TO-17 and SW846-8260. This approach uses multi-bed sorbent tubes, similar to those in indoor air testing, to capture a broader range of compounds. Because larger air or soil gas volumes pass through these tubes, analytes concentrate more effectively, significantly lowering detection limits.

Field Handling and Sample Integrity

Before field use, technicians thermally activate and batch-test each sorbent tube, then seal them with brass Swagelok® fittings to prevent contamination. Once in the field, they unseal the tubes only when sampling begins, then immediately reseal them afterward. This process protects the activated adsorbents from background VOCs. To ensure quality control, teams preserve unopened tubes as trip blanks. These steps help maintain sample integrity from collection through to laboratory analysis.

Enhanced Laboratory Analysis

After collection, samples go to the lab where technicians load them into an automatic thermal desorption (ATD) unit connected to a GC/MS system. The lab then runs EPA Methods TO-17 and SW846-8260. This combination is up to 1,000 times more sensitive than traditional techniques. By concentrating a larger air volume on the sorbent tubes, the method can detect VOCs at levels low enough to meet indoor air action levels—levels often missed by older techniques. Analysts report compounds in nanograms (ng), with a reporting limit of 5 ng. Even detections as low as 1 ng are noted as estimates, useful for identifying low-level or deep plumes.

Sampling Procedure in the Field

Field teams follow Vista GeoScience SOP NFSV101 for collecting soil gas samples using a direct-push probe and Post-Run Tubing (PRT) adapter. After driving the probe to the target depth and exposing the soil, they insert Teflon® tubing through the rod into the PRT tool. They connect the setup to a GEM2000 gas meter to monitor CO₂, O₂, and CH₄ levels while purging the system. Once the gas readings stabilize, indicating pure soil gas flow, they redirect it through the sorbent tube using a vacuum pump. Technicians monitor the flow—kept below 200 cc/min—and collect 1 liter of soil gas, after which they seal and label the sample tube.

Optional Vapor Screening

As an additional step, technicians may screen the soil gas with a Thermo Foxboro TVA1000B vapor meter. The device’s FID (Flame Ionization Detector) measures all hydrocarbons, including methane, while the PID (Photo Ionization Detector) selectively detects aromatic and solvent compounds. Together, they offer a useful preliminary assessment of the soil gas composition before full lab analysis.